In the sheet metal industry,Tools Every Fabrication Fitter. fabrication fitters are crucial for turning raw materials into functional components used in various applications Tools Every Fabrication Fitter.

Fitters rely on a diverse array of tools that enable precise cutting, shaping, and assembling of metal pieces.

Whether you’re a seasoned professional or just starting in the field, having the right tools at your disposal can significantly enhance your efficiency and the quality of your work. Let’s explore some essential Tools Every Fabrication Fitter should have in their toolkit.

Measuring Tools:

Accurate measurements are the foundation of successful fabrication work. Essential measuring Tools Every Fabrication Fitter in sheet metal industry:

- Tape Measure: For taking quick and precise measurements of sheet metal dimensions.

- Combination Square: Used to check and mark 90-degree angles accurately.

- Vernier Calipers: Ideal for measuring thickness and internal/external dimensions with high precision.

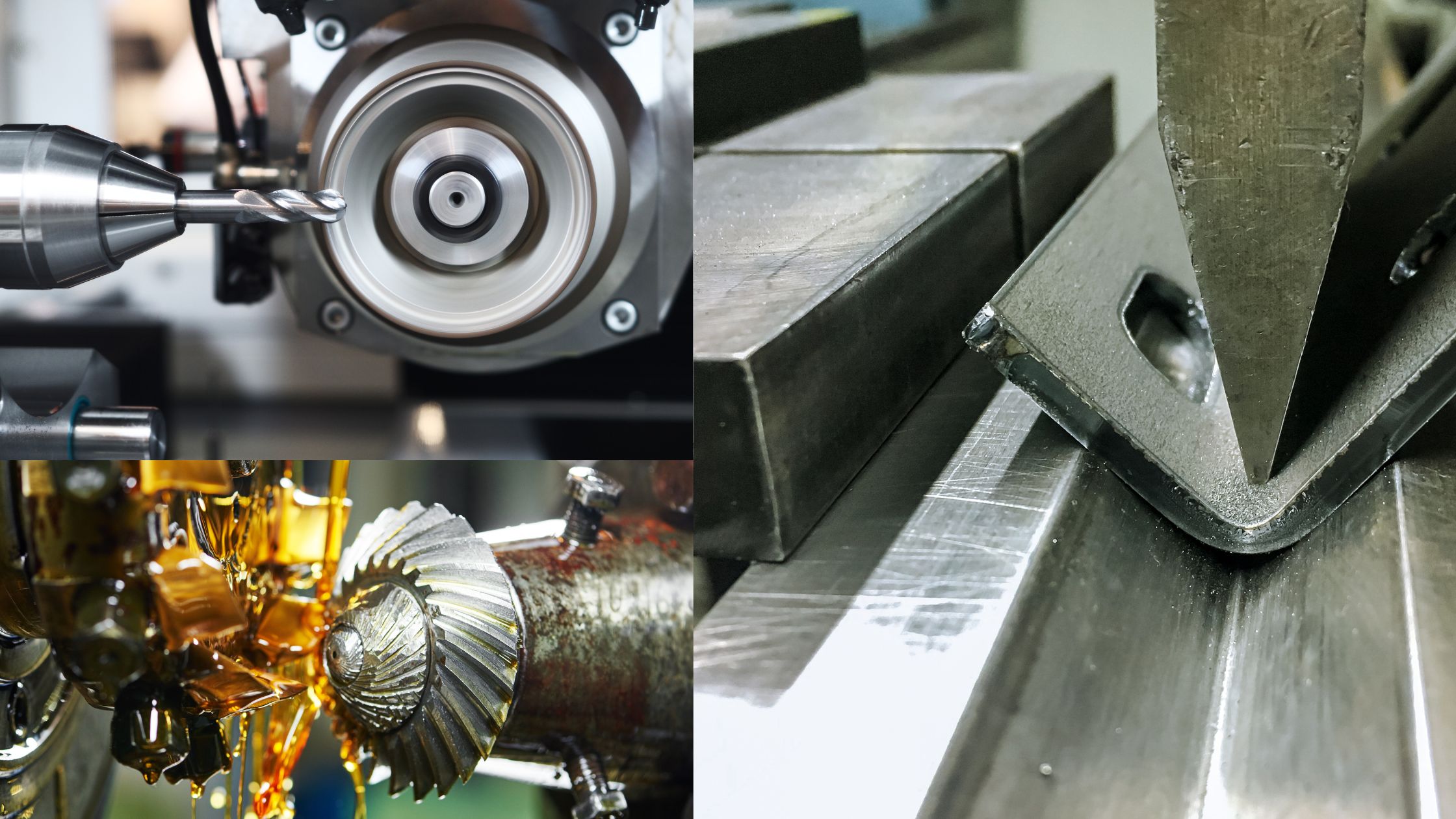

Cutting Tools:

Cutting sheet metal requires precision and the right tools to achieve clean edges. Key cutting tools include:

- Aviation Snips: Designed for cutting through sheet metal with ease, available in straight, left-cut, and right-cut versions.

- Tin Snips: Perfect for cutting curves or intricate shapes in thinner gauge sheet metal.

- Shears: Provide straight and clean cuts, suitable for thicker gauge metals.

Shaping Tools:

Fabrication fitters often need to shape sheet metal to fit specific designs or dimensions. Important shaping tools include in sheet metal industry:

- Hammers and Mallets: Used for bending, shaping, and forming sheet metal without damaging its surface.

- Hand Seamers: Essential for creating precise bends and seams in sheet metal.

- Brake Press: Offers precise bending capabilities for creating complex shapes and angles.

Welding and Joining Tools:

Joining metal pieces together is a fundamental aspect of fabrication work. Key welding and joining Tools Every Fabrication Fitter:

Table of Contents

- Welding Machine: Whether it’s MIG, TIG, or Stick welding, having the appropriate welding machine for the job is essential.

- Clamps and Vises: Hold metal pieces securely in place during welding or assembly.

- Welding Helmet and Safety Gear: Ensure personal safety during welding operations with appropriate protective equipment.

Finishing Tools:

After fabrication and assembly, finishing touches are necessary to achieve a polished final product. Common finishing Tools Every Fabrication Fitter:

- Grinders and Sanders: Used for smoothing out rough edges and surfaces after cutting or welding.

- Deburring Tools: Remove sharp edges and burrs from metal components for safety and aesthetics.

- Surface Treatment Equipment: Such as paint sprayers or powder coating systems for applying protective coatings and enhancing the appearance of finished parts.

Read more…… Visit Our Official Website………Click Here…….

[…] How to Choose the Right Sheet Metal Fabrication Company […]